Our organisation Title Display System Private Limited is one of the reputed manufacturer which established in the year 1993 and comprehensive range of Writing & Display Boards, Smart Classrooms, Office Automation, Study Desk, Stationery Items Etc. We fabricate these products using superior quality raw material, sourced from the leading and authentic vendors of the industry. Our range is in high demand and is reckoned for its incomparable quality features. We offer these at Affordable Rates in marketing our varied clients. Our range is highly durable, have long-lasting finish and reliable.

In the present market scenario there are many manufacturers who produce similar products like us. But in spite of facing competition, we are able to emerge as one of the

leading manufacturer and exporter of various visual display products. Quality With Quantity is Our Main Strength.

Because of the meticulous approach of our staff, we are able to provide our customers with high-quality items.

We have received praise from our esteemed clientele from various domains, including educational institutions.

Our dedication to providing our esteemed clients with clever, new, inventive items that can aid them.

We always work to co-create and sustain enduring connections with every one of our clients.

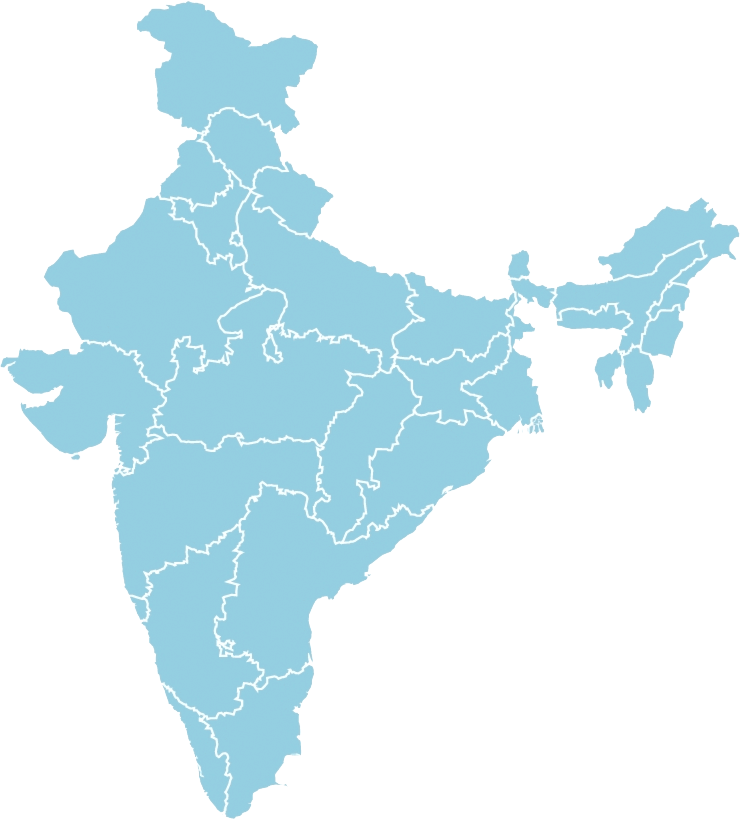

| Our Branches (INDIA) | ||||

|---|---|---|---|---|

| Gujarat (GJ) | Maharashtra (MH) | Rajasthan (RJ) | Karnataka (KA) | Telangana (TG) |

| Rajkot | Surat | Vapi | Nagpur | Jodhpur | Jaipur | Bangalore | Hyderabad |